Driving real ROI by improving safety outcomes

Supporting EHS leaders across the Fortune 500

0

1

.

Intenseye Core AI is empowering safety teams to save lives

0

2

.

Reduce the liabilities associated with non-compliance issues

0

3

.

Minimize time losses and improve overall efficiency

Privacy & ethical AI

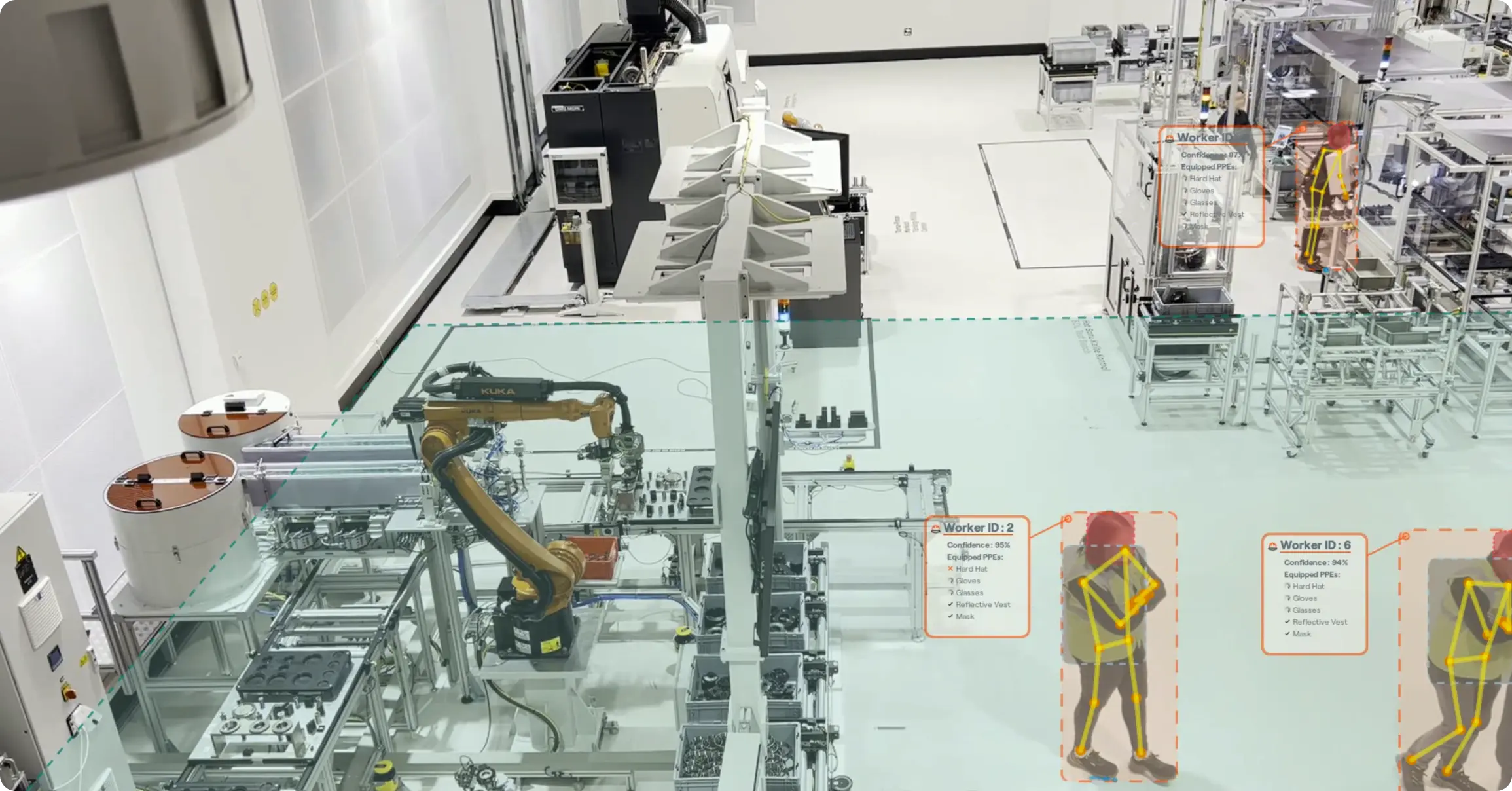

Harness the power of ethical AI for safer workplaces

01.

Gain unbiased insights

Eliminate discriminatory biases by deploying ethical AI, ensuring fair and accurate results.

02.

Adopt a human-centric approach to AI deployment

Address systemic issues with trust and transparency, creating both physically and psychologically safe workplaces for a safer and more efficient environment.

03.

Ensure privacy

Safeguard individual and company data with Intenseye, guaranteeing confidentiality and anonymity.

Your privacy is protected with Intenseye.

XY

XY

XY

XY

XY

XY

.webp)

.webp)

.webp)

.png)